Engine lifter parts and operation tips

Engine lifter parts

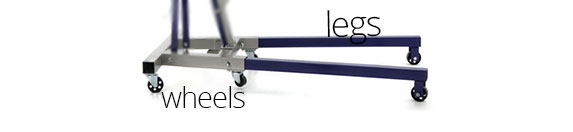

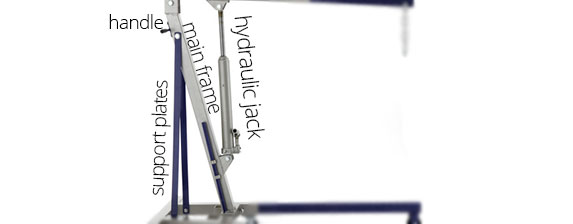

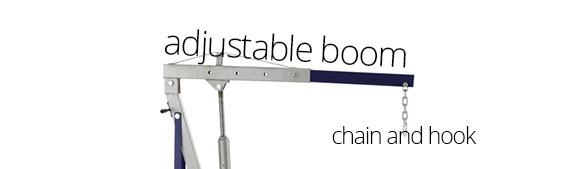

Engine lifter consists of multiple parts than can be divided into three categories – base, body and boom. Each of these categories is responsible for different tasks. Base consists of legs and wheels, body consists of main frame, support plates, jack and some hoists also have handle for moving the hoist, and top part consists of adjustable boom with hook and chain at the end of boom.

Wheels

Engine lifters usually come with two, four or six wheels. Two wheeled hoists can be moved only to front and back, and wheels are mainly used to move hoist, when it hasn’t lifted a load, and when hoist is lifting a load, it cannot be moved. Hoists with smaller maximum lifting capacities usually have four wheels. Four wheeled hoists usually have lifting capacities from 1 ton (2000 lb) to 2 tons (4000 lb). These hoists can be moved in all directions also when they are carrying a load. However, four wheeled hoists may not have the best stability and it may be difficult to move hoists with heavier loads lifted. This is why six wheeled hoists are more common for engine lifters with higher load capacities. Six wheeled hoists, same as four wheeled, can be moved in any direction. These lifters are more stable, so they are mainly used for engine hoists with lift capacity from 2 tons (4000 lb) to 8 tons (16000 lb). Besides these two to six wheeled hoists, there are also some engine lifters without any wheels at all. These are called static hoists. Static hoists usually have special mechanism that allows turning all body of the hoist to side, same as cherry picker cranes, so when engine is lifted out of the car, hoists boom can be turned to sides, so engine can be taken out of the car and placed on the ground or on engine stand.

Legs

There two types of engine hoists – regular and foldable. Regular engine hoists have legs welded to main frame of the hoist. Foldable engine hoists have foldable legs, which can either be folded up or down, so the hoist takes up less space, or can be taken off. Foldable hoist legs can be attached to engine hoist with special plugs or screws. Those plugs or screws are made from durable and thick steel metal, so they can withstand very high loads and practically are equally strong to welded legs. Foldable legs are useful, if you want to transport the hoist or want to fold the hoist to store it in your garage or workshop, so it does not take up as much space. Foldable engine hoist can be folded in three or more times smaller size than a regular hoist. Also some engine hoists have extendable legs. This is useful when engine is located further into the engine compartment and is hard to reach. Then engine hoists boom can be extended to reach the engine and hoists legs can be extended in same distance to better balance the hoist.

Main frame with support plates and handle for moving

Main frame of engine hoist is the part that holds together legs, jack and boom. Main frame is like backbone of the hoist. Main frame is made from durable, thick steel and is one of the most durable parts of the hoist, as it needs to withstand the highest load. Most engine lifters have support plates on sides of the main frame. These plates are used for support and stability of the hoist. Main frame also has got a special mount for hydraulic jack. Bottom part of the jack needs to be attached to this mount. Some engine lifters have got a handle for moving on the back of the main frame. The handle is very simple and usually can be detached from the hoist if not used. Most handles have rubber grips for extra comfort when moving the engine hoist.

Jack

Jack on the hoist is responsible for lifting of load. Engine hoists jack has got a hydraulic cylinder, which works by adding and lowering pressure with oil inside of the jack. Bottom part of hydraulic jack gets mounted to the main frame of the hoist and top part to the boom. Bottom part is static and needs to hold the load, while top part is movable and is responsible for lifting and lowering the load. There are two important parts of a hydraulic jack – pumping bar and bleed valve. Load lifting process is done with the pumping bar. This bar needs to be inserted into a special hole that is located on the bottom of the jack. After that, a person operating the hoist needs to pump this bar, so pressure in the hydraulic cylinder increases and jack is able to lift boom with a load attached to the end of it. For lowering the load there is a special bleed valve located on the bottom of the jack. This valve needs to be slowly turned in order to lower the load. Lowering process is much faster than lifting process, so it needs to be done with extra caution. Hydraulic jack usually have few times greater maximum load capacity than engine hoist itself. This is because hydraulic hoist can fail more easily and it needs to stand higher loads. So don’t get confused if, for example, engine hoists maximum lift capacity is indicated 2 tons (4000 lb) and hydraulic jacks lift capacity is indicated 8 tons (16000 lb). This does not mean that engine hoist is able to lift 8 tons (16000 lb). Always look at maximum allowed capacity of all engine hoist tool together, not just the hydraulic jack.

Boom

Engine hoists boom is responsible for holding the load. Most foldable engine hoists have adjustable boom. These booms can be extended so they can reach engines that are located further into the engine compartment. Most booms have four adjustment positions. Each position has different maximum allowed lift capacities. If boom gets extended further, the maximum allowed lift capacity decreases. For example, engine lifter with maximum lift capacity of 2 tons (4000 lb) is going to have adjustment positions of 2 tons (4000 lb), 1.5 tons (3000 lb), 1 ton (2000 lb) and ½ ton (1000 lb). Maximum lifting capacities of each position are usually indicated on the side of the boom with large letters and can also be found in the safety and usage instructions of the lifter. You also need to take into account the measurements of car and engine you need to lift, and the weight of the engine, so you can accurately calculate, which engine hoist will be suited for your needs.

Chain and Hook

Most of the engine hoists come with chain and hook attached to the boom of the hoist. On some hoists you need to buy this hook, or hook with chain separately. The purpose of these parts is to hold chains that get attached to the engine or hold load leveler. Chain and hook can be replaced if, for example, they do not have the right length or in other way do not fit your needs. Chain and hook are also made from high tensile steel.

Engine hoist operation

Engine hoist may not be a very complex tool, but there are few important points to know, when operating a hoist. Engine hoist works with extremely heavy loads and wrong usage of the tool can be very dangerous. So here are some key points to remember, before using an engine hoist.

Before usage:

- Read the instructions – Always remember to read all usage and safety instructions of the hoist before using it, also if you have used another engine hoist before. Not all hoists are the same and most of them have their own specifics.

- Check each part and mounting screw of the hoist – look for any cracks, broken parts, loosen screws before using the hoist.

- Lubricate moving parts regularly – Remember to lubricate all moving parts of the hoist regularly, ideally before usage in each day. This will ensure that hoist will work properly for longer period of time.

- Check area around the hoist – Before using the hoist, check the area around it, if there isn’t any debris or objects that can interfere with the lifting process. Also make sure that surface where you will be using the hoist is solid.

Lifting:

- Prepare engine – Disconnect any wires, bolts, tubes and other parts from the engine, so it can be lifted from the engine compartment. After that, locate attachment points on the engine, where lifting chain needs to be attached. These points are usually located on the front and back, or on the sides of the engine.

- Prepare hoist – Again, check if all parts of the hoist are in working condition and there are no cracks or loosen parts. Move the hoist in position, where it can reach attachment bolts of the engine. If hoists boom is extended, check if weight of engine does not exceed the maximum weight limit of the hoist. Also check, if hoists boom is long enough to fully lift engine out of the engine compartment, and prepare place where you are going to put the engine, as engine hoist is not designed to store engine for long time. Usually this means placing engine on engine stand.

- Lift engine up just a bit – First, when lifting chains are correctly attached to the engine, raise it just a bit to see, if it is properly leveled and if all parts have been detached from the engine. If engine is not leveled, get yourself a load leveler, which needs to be attached at the end of the engine hoists hook. This tool will level load correctly on both sides, so engine does not swing when being lifted.

- Lift engine fully up by pumping the hydraulic jack – This may take a longer time, depending on the height engine needs to be lifted and weight of the engine.

- Carefully transport the hoist with engine away from the car – Pay attention if engine is leveled and does not start to wobble. Wobbling and swinging of engine may increase the load, which can result in failure of the hoist.

- Store the engine on the engine stand or other place you have previously prepared.

Lowering:

- Carefully lower the engine – This is an important step and needs to be complied with additional caution. Lower the engine by slowly turning the bleed valve on bottom of the hydraulic jack. Remember to turn the valve slowly, as lowering process of the load will be much faster than lifting process.

- Store engine on the engine stand or other place you have prepared – When engine is lowered to necessary position, attach it to the engine stand or place on other place you have previously prepared.

- Remove all attachment chains from the engine – When engine is safely stored on engine stand or other place, detach lifting chains and remove all safety bolts of the hoist from the engine.

- Floor Jack Storage Ideas and Tips - November 19, 2019

- Tips for Using a Car Jack - November 12, 2019

- How Often Should You Wash Your Car in the Winter? - November 5, 2019

Leave a Reply