What is Engine Stand and From What Parts it Consists

What is engine stand and what is it used for?

Engine stand is a tool that is used for storing an engine, while making repairs to engine or car. Same as engine hoists, engine stands also have few types and are suited for different load limits. Most common engine lifters will hold from ½ ton (1000 lb) to 2 ton (8000 lb) heavy engines. Engine gets mounted to adjustable mounting arms that are located on the top of the stand. Most stands allow rotating engine 360 degrees around, so mechanic can access all parts of the engine more conveniently. Some engine stands even allow changing mounting head position from horizontal to vertical, which allows locating hard to reach parts of the engine easier. The price of engine stands starts from as low as 20 dollars for engine stands with maximum capacity of ¼ ton (500 lb) and goes over hundred dollars for stands with maximum capacity over 2 tons (4000 lb).

Engine stand parts

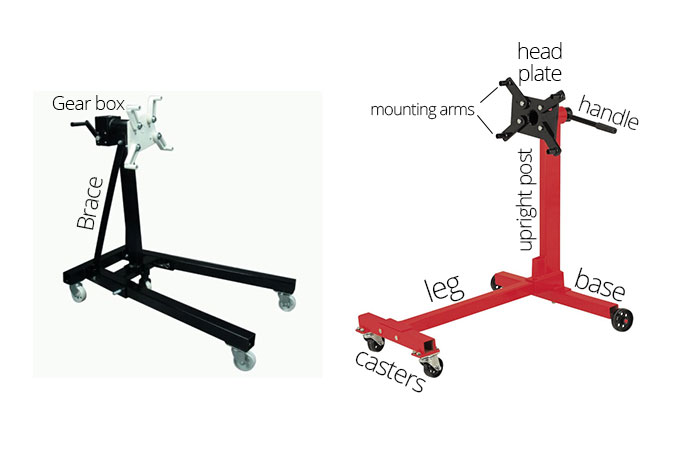

The basics of an engine stand are same for all stands, but each engine stand can have its specifics like different post positions, leg and wheel count and others. Next, I am going to describe from what parts an engine stand is made, what varieties of these parts different engine stands have and how those parts impact operation of the stand.

Base, legs and casters

The base of engine stand, similar as engine hoist, consists of legs, casters and base tubes. Engine stands usually come with 3 – 6 casters. The most common wheel count for engine stand is four. Four wheeled stands are stable and do not take as much space as six wheeled stands. Some stands have only three casters. These stands are good for engine with weight less than ¼ – ½ ton (500 – 1000 lb), but usually are unstable with heavier engines. Five and six wheeled stands are made for larger and heavier engines and will support load over 2 tons (4000 lb). Smaller engine stands have only one leg, while larger stands have two legs, similar to engine hoists. Stands with two legs are more stable and usually can be used with larger engines. Some engine stands are foldable, which means that one or all legs of the stand can be folded, so it takes up less space when not being used. When stand is going to be used, legs need to be locked in the right position with special, durable steel locking pins. Today, most engine stands can be disassembled so they take up less space and are more easily transportable.

Post and braces

Post of the engine stand is made from heavy duty, durable and thick steel, so it can support heavy engines on the stand. Basic stands made for less heavy engines usually have only upright post and do not need any support braces. Stands that can hold heavier engines (2 tons and above) usually have additional support braces for extra durability and safety for holding engines with weight capacity close to the allowed weight limit of the stand.

Rotating mechanism and handle

The most important part of engine stand is head. It consists of rotating mechanism and mounting plate. Rotating mechanism is located into the head of engine stand. On the back of the head there is a turning handle. With help of this handle, a person operating the stand is able to turn engine stands head and the mounted engine 360 degrees around. On the head there is a special hole, or multiple holes, for locking the mounting plate with engine from rotating. This way you can rotate the engine to a position you need and lock it there with a locking pin. Some engine stands have a special gear box instead of turning handle. Turning heavier engines may be difficult and requires a lot of strength. This special gear box makes engine rotation a lot easier. There are also some engine stands that have automatic rotating mechanism that makes process of rotating a heavy engine practically effortless.

Head plate and mounting arms

Engine stand parts that are responsible for mounting the engine are head plate and mounting arms. Mounting arms are screwed to the head plate and can be adjusted to fit most engine blocks. Most engine stands come with four mounting arms. Engine needs to be mounted to the stand with special mounting bolts. Some engine stands come together with mounting bolts, but usually they need to be bought separately and can vary in size and length between different engine blocks.

- Floor Jack Storage Ideas and Tips - November 19, 2019

- Tips for Using a Car Jack - November 12, 2019

- How Often Should You Wash Your Car in the Winter? - November 5, 2019

Leave a Reply