Most Common Floor Jack Problems and Their Fixes

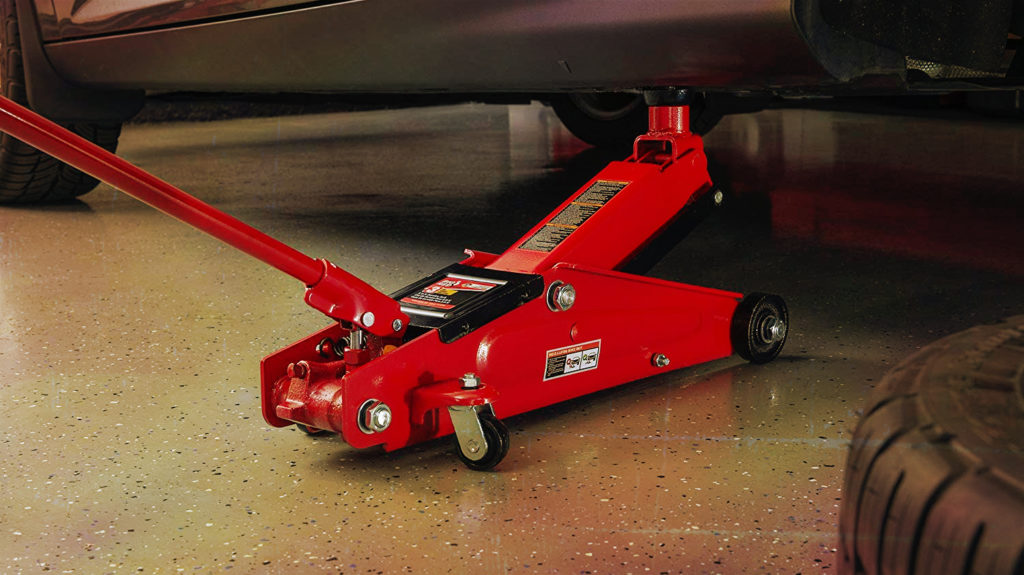

The floor jack is a wonderful tool to have – it easily lifts vehicles like they are made of foam and it allows you to safely examine and fix a car with ease. Whether we’re talking about changing a flat tire or tweaking with its undercarriage, a hydraulic floor jack can be invaluable in a lot of situations. Floor jacks are not immune to problems and malfunctions too, however, and sometimes they too require fixing. So, let’s take a look at the most common floor jack problems and their fixes.

What exactly is a floor jack?

If you’re at a loss as to what we’re talking about, let’s take a quick look at what a floor jack even is before we look into how to fix a floor jack.

The floor jack is a hydraulics tool with a saddle, rollers, and a hydraulic pump that can easily lift an entire vehicle from the side and keep it in the air while you safely sneak underneath it. A well-operational floor jack is both safe and easy to use and can remain that way for years if it’s been properly maintained in accordance with its manufacturer’s specifications. A good floor jack will also have a number of fail-safes so that even if something is out of the ordinary, it won’t bring the vehicle crashing on top of you.

Nevertheless, floor jacks are just tools like any other, and they can indeed break when mishandled. Knowing how to inspect and maintain them, as well as how to perform hydraulic floor jack repair is crucial if you want to use your floor jack without any hiccups.

What are the most common floor jack problems you may face and how to fix them?

So, what are the most standard floor jack problems you might encounter and how should you perform quality hydraulic jack repair for each of them?

The floor jack won’t lift enough weight

The floor jack’s sole purpose is to lift weight and to keep it in the air securely. There are a number of reasons why this might be happening and to perform an adequate floor jack repair you’ll want to check every one of them. Here are some pointers:

- Make sure you’re not overloading the jack. Even the best floor jack will have a weight limit it can’t and shouldn’t exceed. If you’re trying to overload the jack it will not only explain why it doesn’t work but it may even damage it even more.

- Make sure your floor jack has enough hydraulic oil. Both having too little and too much hydraulic oil can cause a floor jack to malfunction. Make sure that your floor jack always has oil up to the oil line and not too far above or below it.

- Lubricate your floor jack. Add oil to all moving parts to make sure that nothing is stuck and everything is moving smoothly.

- Release air that might be trapped in the jack’s hydraulics. This is one of the more common problems that catches people by surprise. Air can sometimes get trapped in the jack and prevent it from working properly. Thankfully, this is an easy floor jack repair to perform – just remove the screw of the oil filler and place the jack’s release valve so that it’s counter-clockwise to the handle.

- Tighten the release valve. If the release valve is loosened, it’d be normal for the jack to not lift enough weight.

The overload valve has been turned

The overload valve is a safety feature that prevents it from working if you try to lift too much weight with it. If you’ve accidentally turned it on then you should seek the help of a hydraulics expert to fix it – just changing the valve back will release the tension spring and cause it to malfunction.

Your floor jack is leaking

Oil leakage can sometimes happen to a floor jack. Replacing the O-rings in the jack will usually fix this problem and help the jack work properly from thereon. Just release the valve screw, drain the fluid from the jack, place the new O-rings, refill the jack, and place the valve screw back on.

Your floor jack is leaking a milky or foamy liquid

This is a separate problem as it means that there is a water or air mix with the oil. This happens if you aren’t frequently wiping the dust from the drain plug with a rag. To fix this, simply change the oil and clean the drain plug.

Breaking, bending or cracking of the floor jack

This is one major problem that shouldn’t be fixed but will simply render a floor jack unusable. The jack’s frame is what keeps it stable and what allows it to safely and securely keep large vehicles in the air – if the frame of the jack is compromised in any way, do not attempt to fix it – just decommission the jack and look for a replacement.

What are some of the general floor jack maintenance tips you should keep in mind?

Now that we know how to fix a floor jack when it malfunctions, let’s quickly go over the proper maintenance we should do to avoid malfunctions in the first place.

- Always store the jack on its base and not on its side, to avoid leakage.

- Make sure that the piston and the pump are pulled in when you store your jack.

- Make sure the oil is always at the appropriate level – not too much above or below it.

- Protect the jack from both moisture and dust when you’re not using it.

- Clean your jack well before and after every use.

- Change the jack’s oil from time to time even if it doesn’t need refilling.

- Carefully inspect the jack every time before using it.

- Periodically bleed air out of the jack if you notice it’s not working at 100%.

- Floor Jack Storage Ideas and Tips - November 19, 2019

- Tips for Using a Car Jack - November 12, 2019

- How Often Should You Wash Your Car in the Winter? - November 5, 2019

Leave a Reply